One kind of production

process at vendor location is subcontracting. In Navision we cannot create

Subcontracting Order directly because it is re-routed through released

production order. Please follow the steps to create subcontracting cycle

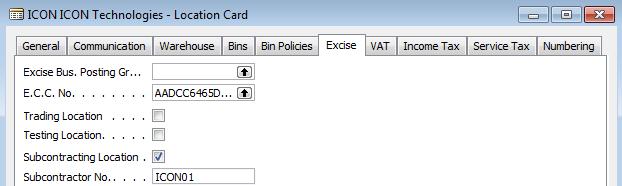

Creation of Location Card

As

said above, it is process at supplier location and it is mandatory to create

location in location card and tag as subcontracting location. See the following

Go to Warehouseà Setup à Locations

In Excise Tab, We need to

declare as this location is subcontracting location as said above. This location needs

to tag to Vendor card of “Icon Technologies” then Subcontractor No. ‘ICON01’will come automatically here

Tagging Location to Vendor Card:

We had completed and

Subcontractor creation and respective linkage. As I said before Subcontracting

is part of Production process so that we need to define Routing. Now let’s see

detail routing process.

As part of routing process

it is necessary to define either “Work Center” or “Machine Center” as per your

license. Here I am creating Work Center for respective routing.

Go to Manufacturingà Capacities à Work Center

General Tab:

- Work Center No. has been generated from Number Series

- Enter Work Center Name

- Select Work Center Group Code from the list (It is used when you are calculating efficiency of similar type of work centers)

Posting Tab:

- Select “Subcontractor No.” from the vendor

list (This is the area we tag this particular work center is used for ICON

Subcontracting.

- System automatically

will select Flushing Method as Manual. If you are following different then

select from the drop down

- Select Gen. Prod. Posting Group from the list – For finance Use

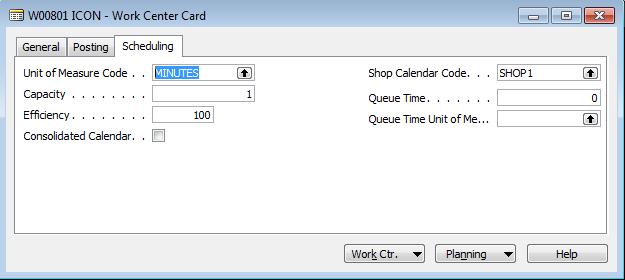

Scheduling Tab:

- Enter Unit of Measure

code as per the Subcontractor (Minutes, Days, Hours)

- Enter Capacity and Efficiency

as defined above, Change the values if required

- Select the Shop Calendar code from the list (It will define Subcontractor Calendar and it is a part of our production planning)

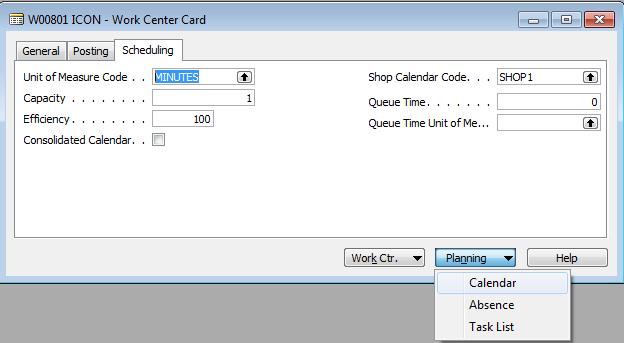

Once you defined Shop calendar code then it is

necessary to run the calendar.

Go to the Planning Menu à Calendar

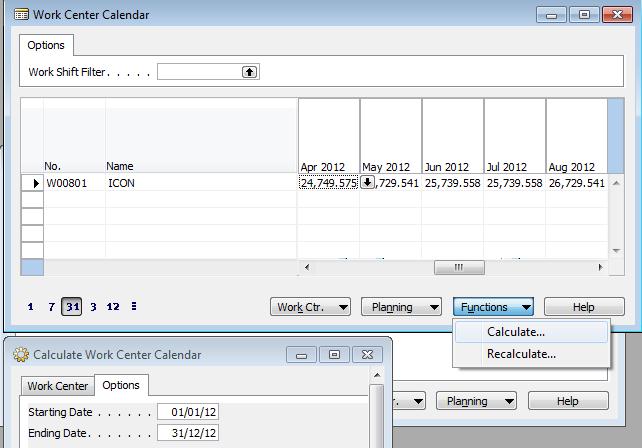

- Work Center Calendar

window will open then Click Functions

à Calculate

- In Calculate Work

Center window Go to Option Tab then enter Start Date and End date then Click OK

- Please note that

Shift has been defined in the system

- As per the diagram below Calendar entries will be generated

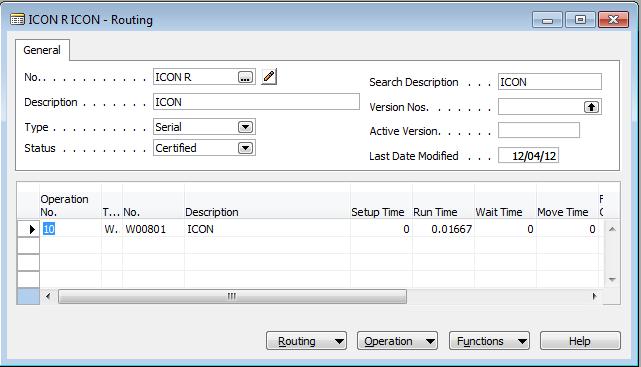

Routing Creation:

Go to ManufacturingàProduct

DesignàRouting

- Generate Routing No.

manually or through System

- Enter Description

- Enter Operation No.

as 10

- Select type as Work Center

- Select Your work

center no. from the list

- Enter run time (In

Work Center card we defined UOM as Minutes so here enter run time approx.

in minutes)

- Change the status to Certified

Creation

of Semi-finished Item -- Raw Material Item – Production BOM

Semi-finished

Item:

Go to Manufacturing à Production Design à Item

Check the following fields:

- Item No.

- Item Description

- Base Unit of Measure

- Invoicing Tabà Gen. Prod. Posting Group, Inventory

Posting Group

- Replenishment Tabà Replenishment System Should be a Prod. Order

- Need to attach Prod. BOM No. and Routing. (we will see after creation of BOM)

Raw Material Item

- Item No., Item

Description, Base Unit of Measure

- Invoicing Tabà Gen. Prod. Posting Group, Inventory Posting

Group

- Replenishment Tabà Replenishment System Should be a Purchase

BOM

Creation:

Go to Manufacturingà Product Design à Production BOM

Tagging

Production BOM & Routing into Semi finished Item

Go to I 1001 item Card and select the following:

- Routing No. – Select

from the Routing list ICON R

- Production BOM No. –

Select from the Production BOM List

(Note: We have

finished setups and linkages. Now we will see Subcontracting Process)

Creation

of Release Prod. Order for Subcontracting

Go to Manufacturing à Executionà Released Production Orders

Steps to create:

- Select Production No.

by clicking F3

- Select Source Type as

Item and Source No. is I 0001 (Our semi-finished Item)

- Enter Quantity and

Due date

- Posting Tab à Select location

- Click Functionsà Refresh

- System will create

line based on your BOM and Routing

- To See Components

Click Lines à Components

- To See Routing Click

Lines à Routing

Released Production

Order:

Click Line à Components

Click LineàRouting

Creation of

Subcontracting Order:

Go to Manufacturingà Planningà Subcontracting Worksheets

After window Opens, Click FunctionsàCalculate Subcontracts.

In Prod. Order routing line Tab, Select

your released Production No. then Click OK

After clicking OK system will generate a line in

Subcontracting worksheet.

Then, Click FunctionsàCarryout Action Message

Your Subcontracting Order has been generated now. Let’s

go have a look.

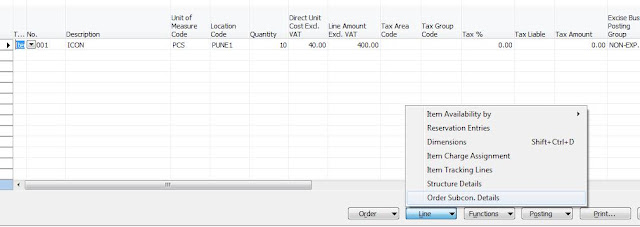

Go to ManufacturingàExecutionàSubcontracting Order

Now we need to send Delivery Challan (57 F4)

using the above Subcontracting Order.

Click LineàOrder Subcon. Details

Here you have two tabs 1. Delivery Details (Used for

Sending material) 2. Receipt details (for receiving Semi finished Parts)

- In delivery, we needs

to enter Delivery Comp. for column then system will calculate Qty to send

column automatically

- If you want to send

bulk raw material to the subcontractor then you can directly put the value

in Qty to send column.

- Specify Delivery

Challan date

- Enter company location

- Click Send

After Clicking Send Delivery Challan Posted get updated

with 1

Go to Delivery Challan

PostedàDrill downà Select your delivery challanàDeliveryàCard

then you can print 57 F4

Receive

Material from Subcontractor:

- Go to Receipt

Detailsà Enter Qty to Accept

- System will

update Qty to consume column

- Give Vendor

Shipment No. and Posting Date in Header column

- Now, We have

adjust consumption against 57 F4. For that

- Click Functionà Apply Delivery Challan

In Apply Delivery Challan window select

App. Delivery Challan No. from the lookup and Qty to Consume is 10.

After Apply delivery Challan Click Receive. Quantity Accepted column is

updated with you Quantity

You can take GRN Print from Posted Receipts.

-- Happy Reading

Hello Srinivas, Thanks for the post. I came across this while trying to do the same in Nav 2016. Looks like a significant revamp. Im going fine till the Subcontracting order. After that when I post it, I am not able to see the Purchase order.

ReplyDeleteAny help is welcome.